- Order Management

- TikTok Shop

- Temu

- Amazon

- About 4Seller

- Shopify

- Inventory Management

- Amazon MCF&FBA

- Seller Tips

- Marketplace News

- Listing Management

- Amazon Shipping

- UPS

- FedEx

- DHL Express

- Creator Bulk Invite

- eBay

- GLS

- Shein

- Amazon MCF

- Inventory Sync

- Multi-channel Store

- Walmart

- Royal Mail

- Walmart WFS

- WooCommerce

- Beginner Tutorial

- Shipping Integration

- Poste Italiane

- BRT

- PayPal Tracking Sync

- ShipHero

- Shipping Label

- Stripe Tracking Sync

- UniUni

- USPS

- Yodel

- GOFO

- CIRRO

- Correos

- Correos Express

- Deutsche Post

- DHL Parcel

- Etsy

- Evri

- FBM

- OTTO

- Kaufland

- 3PL

- Logistics Rule

- CaiNiao

- Chronopost

- Cdiscount

- ShipBob

- SPU Catalog

- AliExpress

- DPD

- Request Review

- DHL

- Price Sync

- OMS

- Platform Integration

How to Efficiently Handle High-Volume Orders from Shopify, Amazon, TikTok, Temu, and eBay?

By Joline14 Nov,2025

By Joline14 Nov,2025

As e-commerce continues to expand across global marketplaces, sellers are facing a new kind of operational challenge: how to fulfill large quantities of multi-channel orders efficiently, accurately, and at scale.

When orders surge across platforms like Shopify, Amazon, TikTok, Temu, Walmart, Shein, Etsy, Woocommerce, OTTO, Kaufland,Marivia,Aliexpress,Cdiscount and eBay, warehouse teams often find themselves under intense pressure.

Printing labels one by one, picking by order, and double-checking every package quickly consumes hours of valuable time — especially for small and mid-sized operations where staffing is limited.In many cases, warehouse fulfillment—not inventory or marketing—becomes the true bottleneck that limits growth.

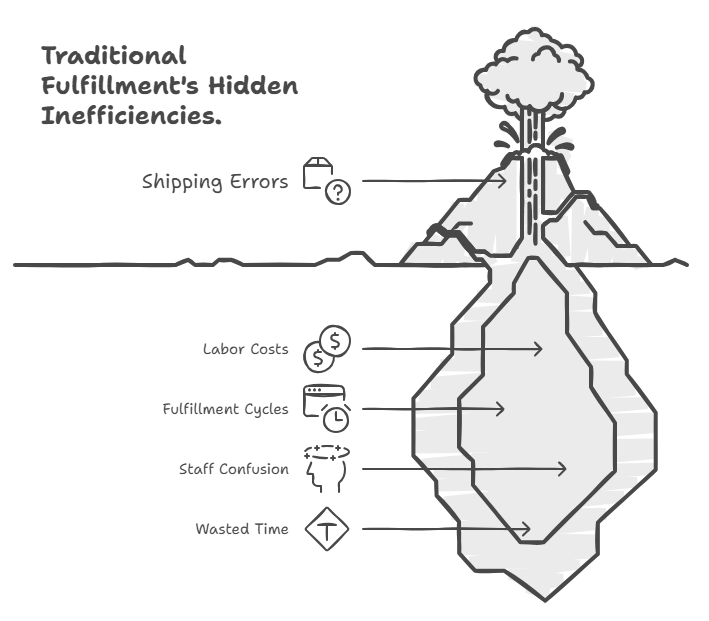

The Hidden Cost of Traditional FulfillmentA traditional picking process is typically order-oriented.

That means staff pick items according to order sequence — retrieving a product from one shelf, moving to another area for the next, and possibly returning to the first shelf minutes later.This constant movement not only wastes time but also creates confusion, especially when similar SKUs are packed for different customers. The result: slower fulfillment cycles, higher labor costs, and an increased risk of shipping errors.

When peak seasons arrive, these inefficiencies multiply. Even experienced teams struggle to keep up with order volumes, and mistakes such as mismatched labels or incorrect packages become almost inevitable.

A Smarter Approach: Grouping Shipments by SKUTo address this operational bottleneck, 4Seller ERP developed the Ship by SKU Groups feature — an advanced warehouse workflow that redefines how bulk orders are processed.

Instead of treating each order as an individual task, the system automatically consolidates orders that contain the same SKU and generates all related documents — shipping labels, packing slips, and pick lists — in organized groups.

This allows teams to:

-

Pick in batches: Collect all units of a particular SKU at once instead of repeating the same route multiple times.

-

Print in bulk: Generate all labels and slips for the SKU group simultaneously.

-

Pack directly: Attach the pre-printed labels to the corresponding products immediately, without manual order matching.

This structured, SKU-based workflow turns what used to be a repetitive manual process into a highly organized, data-driven operation.

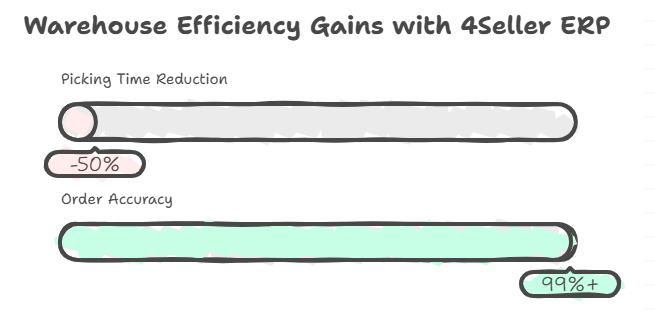

Proven Efficiency Gains

Warehouses that have adopted SKU-based fulfillment through 4Seller ERP report substantial performance improvements:

-

Picking time reduced by up to 50% during high-volume periods

-

Order accuracy exceeding 99%, even with minimal staff

-

Faster turnaround for multi-platform orders, as SKU consolidation simplifies batch processing

By replacing reactive order handling with proactive SKU management, warehouse teams can process hundreds—or even thousands—of packages daily without adding headcount.

Practical Use Cases

-

Cross-Platform Consolidation: Combine orders from Amazon, Shopify, TikTok, Temu, and eBay into a unified SKU-based workflow.

-

Seasonal Demand Peaks: Keep operations stable and on schedule during events like Black Friday or 11.11.

-

Small-Team Operations: Empower lean teams to manage enterprise-level order volumes efficiently.

-

Fast-Moving Inventory: Handle sudden demand surges for viral or trending products without compromising fulfillment speed.

Building Scalable Warehouse Operations

In the modern e-commerce landscape, automation and intelligent workflow design are no longer optional — they are essential for scalability.

4Seller ERP’s Ship by SKU Groups represents this new generation of warehouse optimization: practical, measurable, and built for real-world seller challenges. By transitioning from order-based to SKU-based fulfillment, businesses can finally overcome the limitations of traditional manual processes and deliver the fast, reliable service that customers expect.

For detailed instructions on configuring and using the Ship by SKU Groups feature, please visit the 4Seller ERP Help Documentation.

- Order Management

- TikTok Shop

- Temu

- Amazon

- About 4Seller

- Shopify

- Inventory Management

- Amazon MCF&FBA

- Seller Tips

- Marketplace News

- Listing Management

- Amazon Shipping

- UPS

- FedEx

- DHL Express

- Creator Bulk Invite

- eBay

- GLS

- Shein

- Amazon MCF

- Inventory Sync

- Multi-channel Store

- Walmart

- Royal Mail

- Walmart WFS

- WooCommerce

- Beginner Tutorial

- Shipping Integration

- Poste Italiane

- BRT

- PayPal Tracking Sync

- ShipHero

- Shipping Label

- Stripe Tracking Sync

- UniUni

- USPS

- Yodel

- GOFO

- CIRRO

- Correos

- Correos Express

- Deutsche Post

- DHL Parcel

- Etsy

- Evri

- FBM

- OTTO

- Kaufland

- 3PL

- Logistics Rule

- CaiNiao

- Chronopost

- Cdiscount

- ShipBob

- SPU Catalog

- AliExpress

- DPD

- Request Review

- DHL

- Price Sync

- OMS

- Platform Integration

- 17 Dec,2024

- 17 Dec,2024